A New Era

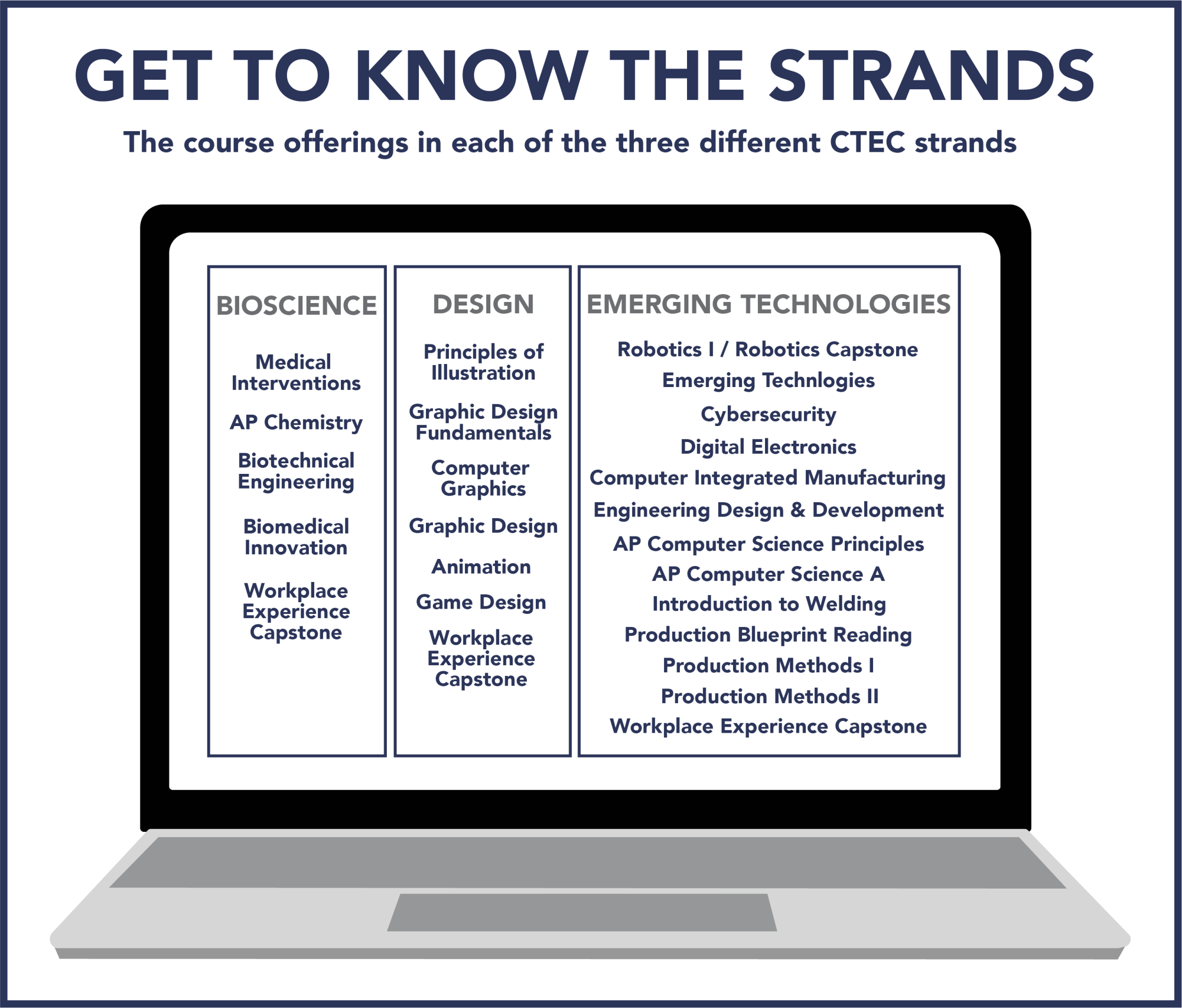

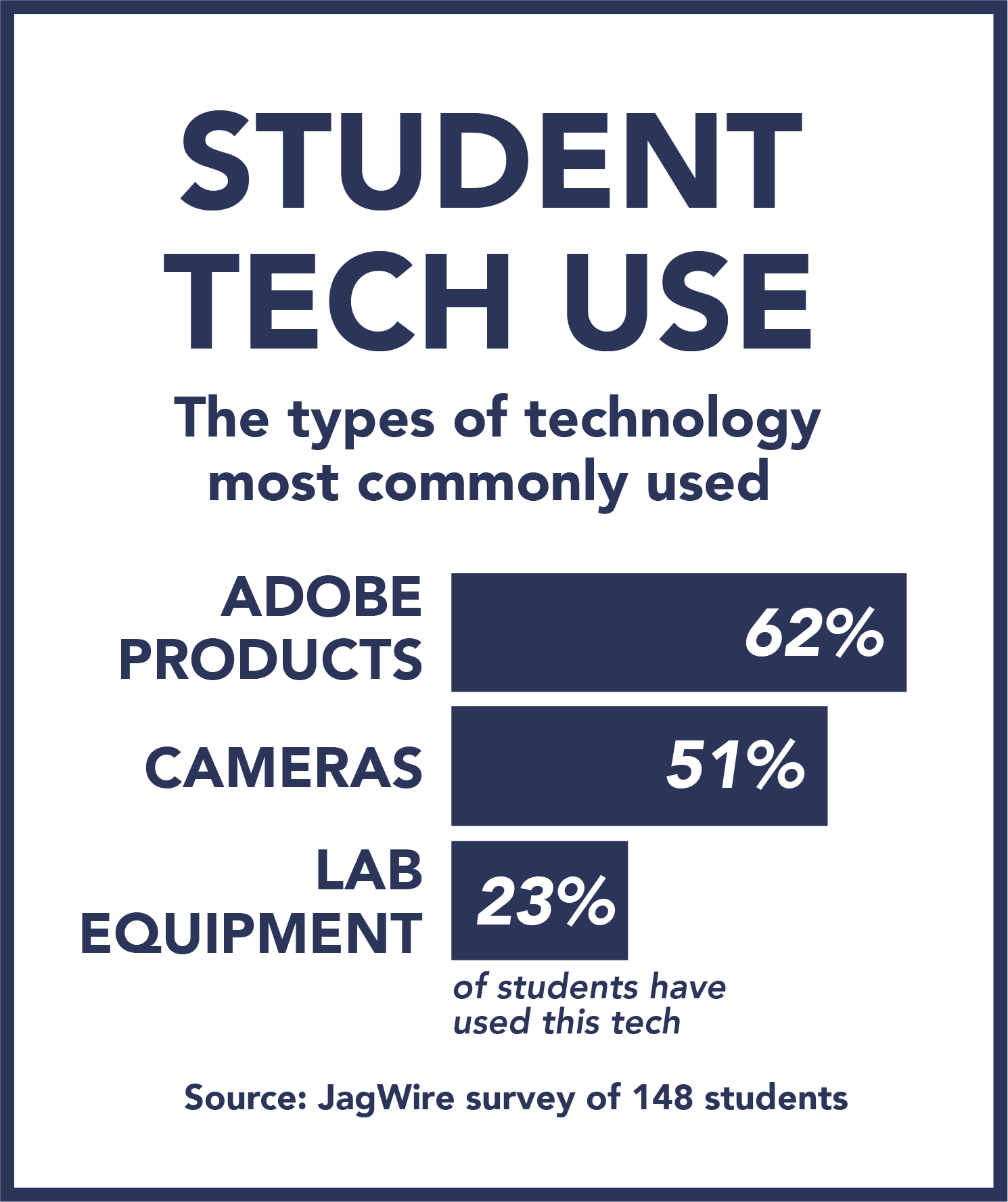

High schoolers are no strangers to technology use. With the school’s shift to 1-to-1 laptop to student ratios and its switch to almost entirely online assignments through Canvas, this daily technology use has gone far beyond the smart phone use known to many adults. However, even beyond this incorporation of technology, the school has provided additional technological opportunities through the district Cedar Trails Exploration Center. CTEC offers students a new way of learning about high-tech career fields through its three programs: the bioscience strand, the design strand and the emerging technologies strand.

Bioscience Strand

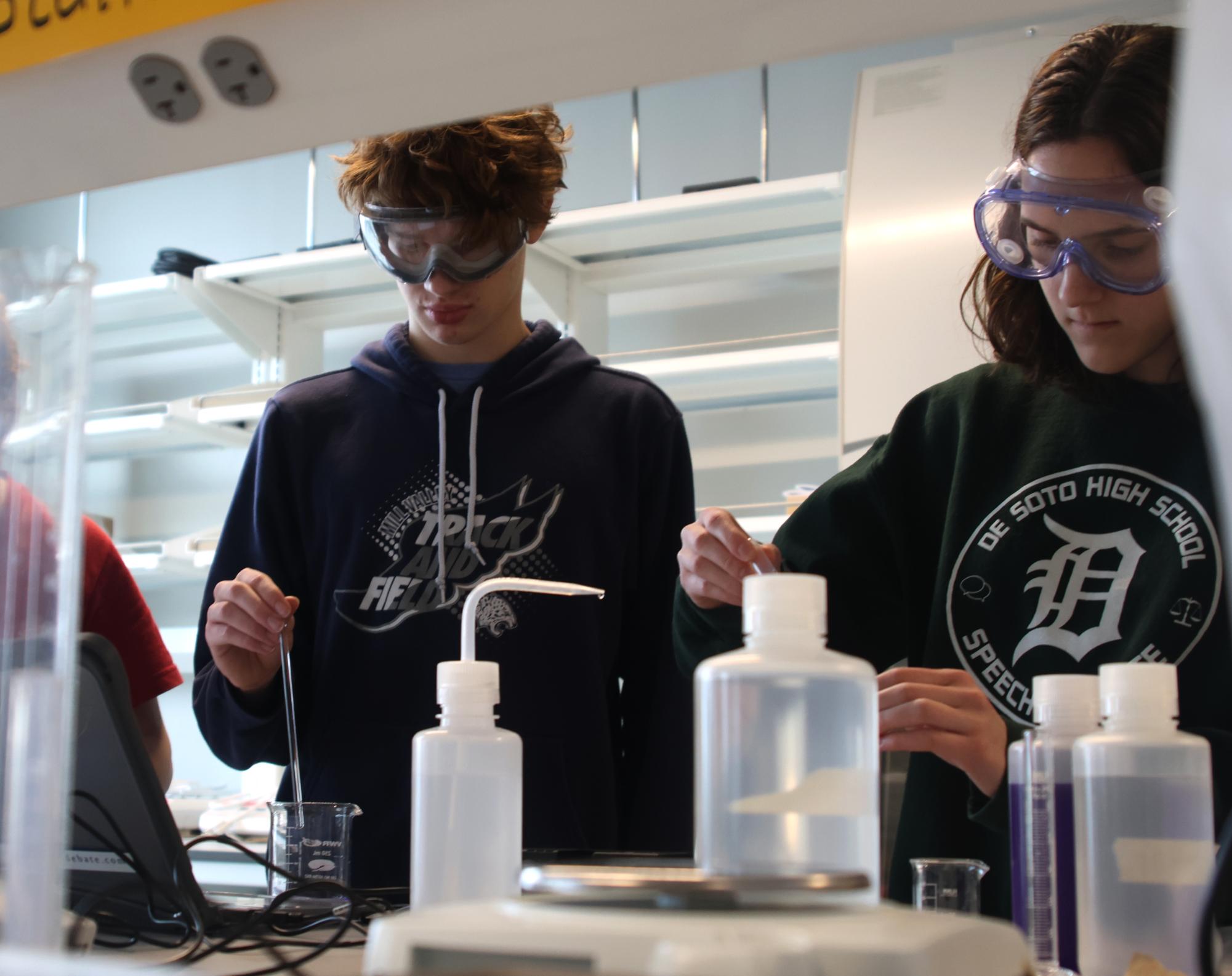

CTEC’s bioscience strand has a wide array of classes covering topics ranging from medicine to chemistry. The medical lab utilized by this strand gives students access to industry-level technology for completing classwork.

Junior Elise Davis utilizes the lab during two of her CTEC classes, Medical Interventions and Biotechnical Engineering. Davis describes the tools she has had access to in her classes.

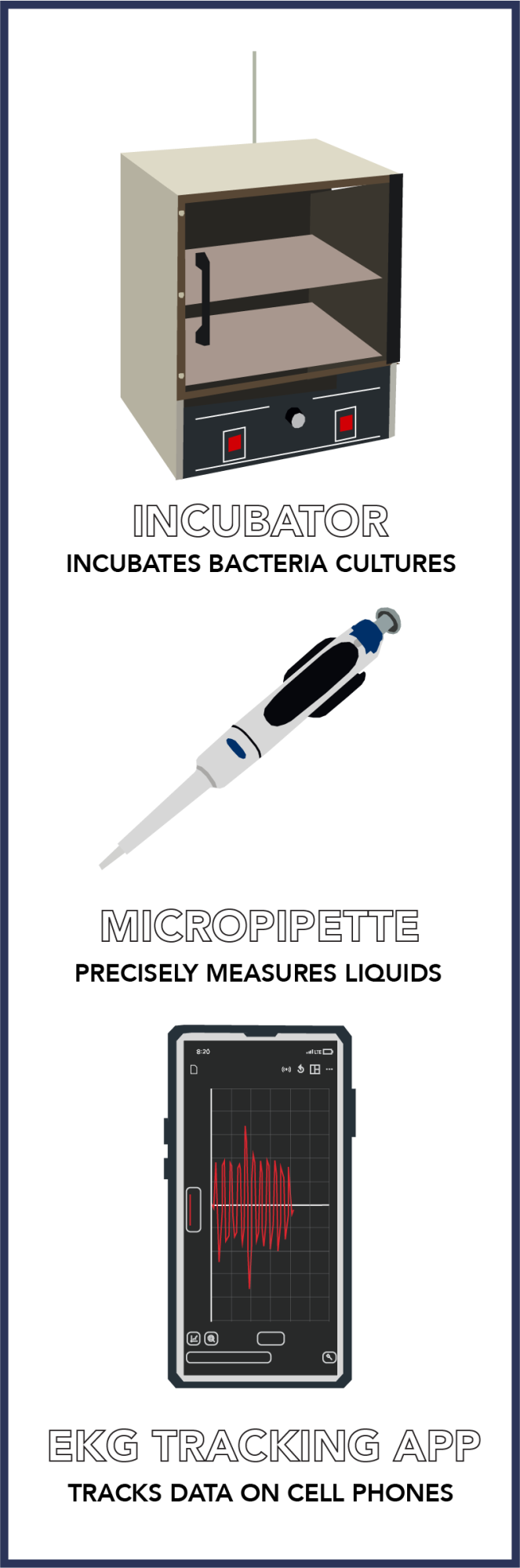

“The med lab has every single lab instrument to offer,” Davis said. “This year, I’ve learned how to use a micropipette spectrophotometer. I’ve learned how to do serial dilutions and use microscopes. There’s also incubators for bacteria. We’ve used agar plates and like grown bacteria and looked at antibiotic resistance. It’s been a lot of experimenting and then concluding from the experiments.”

Being in his second year of CTEC classes, senior Saad Fraitekh has had a lot of experience with the experimentation Davis referred to. According to Fraitekh, the level of experimentation students do in his Biomedical Innovation and Workplace Experience Capstone classes would not be possible with the resources in the medical lab, particularly the incubation chamber.

“For one of our specimens, we were just testing out different strains of bacteria,” Fraitekh said. “We would use a petri dish and we would use the incubation chamber to rapidly grow the bacteria. Bacteria itself will take a couple of days to get enough viable results, but using the incubation chamber it accelerates the process and will get way more bacteria through that.”

Aside from experimenting with bacteria, students have also had access to an electrocardiogram, more commonly known as an EKG, to analyze heart conditions. Senior Bridgit Duffin explains how being able to use an EKG in her Biomedical Innovation and Workplace Experience Capstone classes added to her learning experience.

“Respiratory analysis and heart monitoring and being able to tell what the spikes mean on the EKG, that was just really interesting to me,” Duffin said. “I was like, ‘oh, I knew they were there, but I didn’t know what they meant’ and now I can go in and be like, ‘that looks weird or that looks perfect.’”

Duffin was also able to access the results of the EKG through an app on her phone. This allowed her to learn even more about the data she was collecting.

“[The app] would take a trial and then you could go in and zoom in on certain parts of the graph and really analyze it,” Duffin said. “I thought that was really interesting and a great tool.”

For Davis, the digital technology offered through CTEC’s medical lab is not just useful in-class, but also in gaining experience which will aid students’s future careers.

“I think it’s really nice having access to the facility because we get to practice different technologies that we’re going to use in industry later on in life,” Davis said. “We can learn and work with them now and get really experienced and good at them. Then when we go into our careers in the future, we will already know how to use them.”

Design Strand

The medical lab is just the beginning of the technology CTEC offers students. For those involved in the design strand, resources include both computer programs like Adobe products and also machines like a T-shirt press, sticker printer and laser cutter.

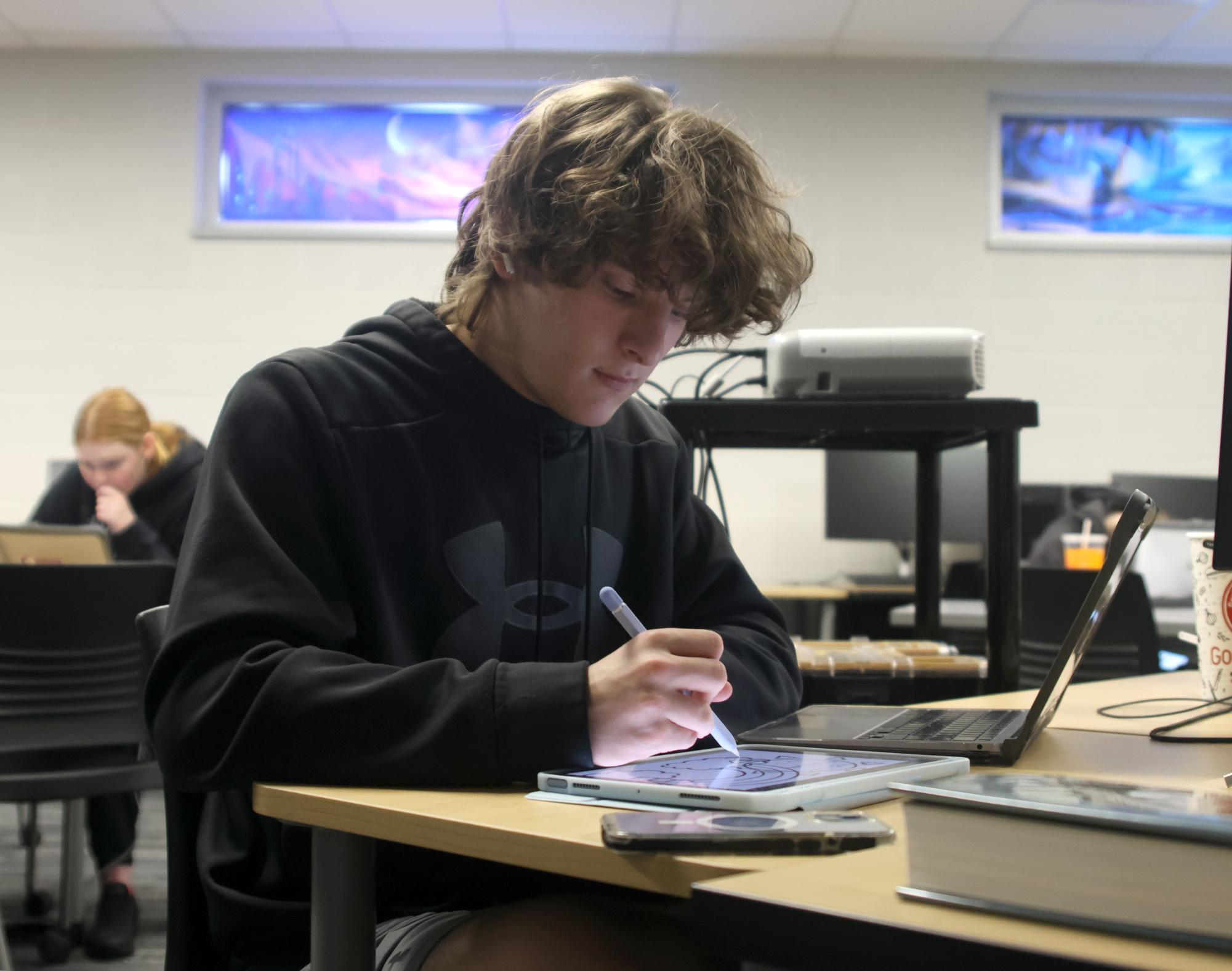

The three Adobe products most commonly used by the students in the program are InDesign, Illustrator and Photoshop. Junior Ayden Brown explains that in his graphic design Workplace Experience Capstone class, these programs are essential.

“Adobe products are extremely, extremely important, especially for graphic designers,” Brown said. “They really offer a variety of tools no matter what. Adobe Photoshop is really good for sketching out designs at first and manipulating various images if need be. Illustrator, the primary one that I feel like I’m the most experienced with and specialized in, is really good for creating vector design.”

Having access to these products allows students like senior Mackenzie Simpson to make projects using contributions from multiple programs at once in her graphic design Workplace Experience Capstone class.

“I’m actually working on a project right now with a group where we’re doing a cookbook,” Simpson said. “We’ll use Procreate to draw illustrations and I’ll use Illustrator. Then we’ll put those files of the illustrations of the food into an InDesign file, so that makes a nice little cookbook.”

Despite their useful capabilities, computer programs are just the beginning for many CTEC graphic design students. Students also utilize other forms of machinery and technology to bring their designs to life. Senior Abby Sommerfeld has been taking classes at CTEC for two years now, and has been able to get to know the potential this technology has.

“Last year, I got really into learning how to use the machinery they have [at CTEC],” Sommerfeld said. “They have a laser printer and a sticker machine and we’ve had some problems with the sticker machine. It just wasn’t printing at a quality we know it can print at, so I spent a good couple of hours just reading the manual on my own in class just because I really want my sticker to be high-quality.”

(By Avery Cole)

Brown explained that having access to such high-quality technology simplifies the process of creating real versions of designs. He describes the process of printing out a sticker in his classes.

“I’ve been designing a lot of stickers recently, personal ones, but I’ve also designed for specific projects that we’ve had in the class,” Brown said. “It’s really such a simple process. You just have to create a couple of guidelines in the programs and then you send it into the program for a specific machine and it just does it all for you. It’s really convenient.”

Aside from sticker making, the T-shirt press is another useful way students can see how their designs might apply to the real world. Sommerfeld explains a project she is working on for her graphic design Workplace Experience Capstone class and how utilizing the sticker printer to bring her vision to life.

“The most recent project would be the Relay for Life shirts,” Sommerfeld said. “Basically, everyone in the class is making a design for a T-shirt and at some point we’ll vote on them. Then we’ll get them all printed and cut out.”

The wide access to technology in the graphic design strand of CTEC reflects the wide array of jobs in graphic design, according to Sommerfeld.

“It helps you just learn that you can create the projects they give us,” Sommerfeld said. You actually make stuff. They will print the stickers that you make for a project. They will let you print on the laser printer if you want to make something for your friends or family. It helps you learn that there’s such a broad world [of graphic design] and there’s a place for anyone.”

Emerging Technologies

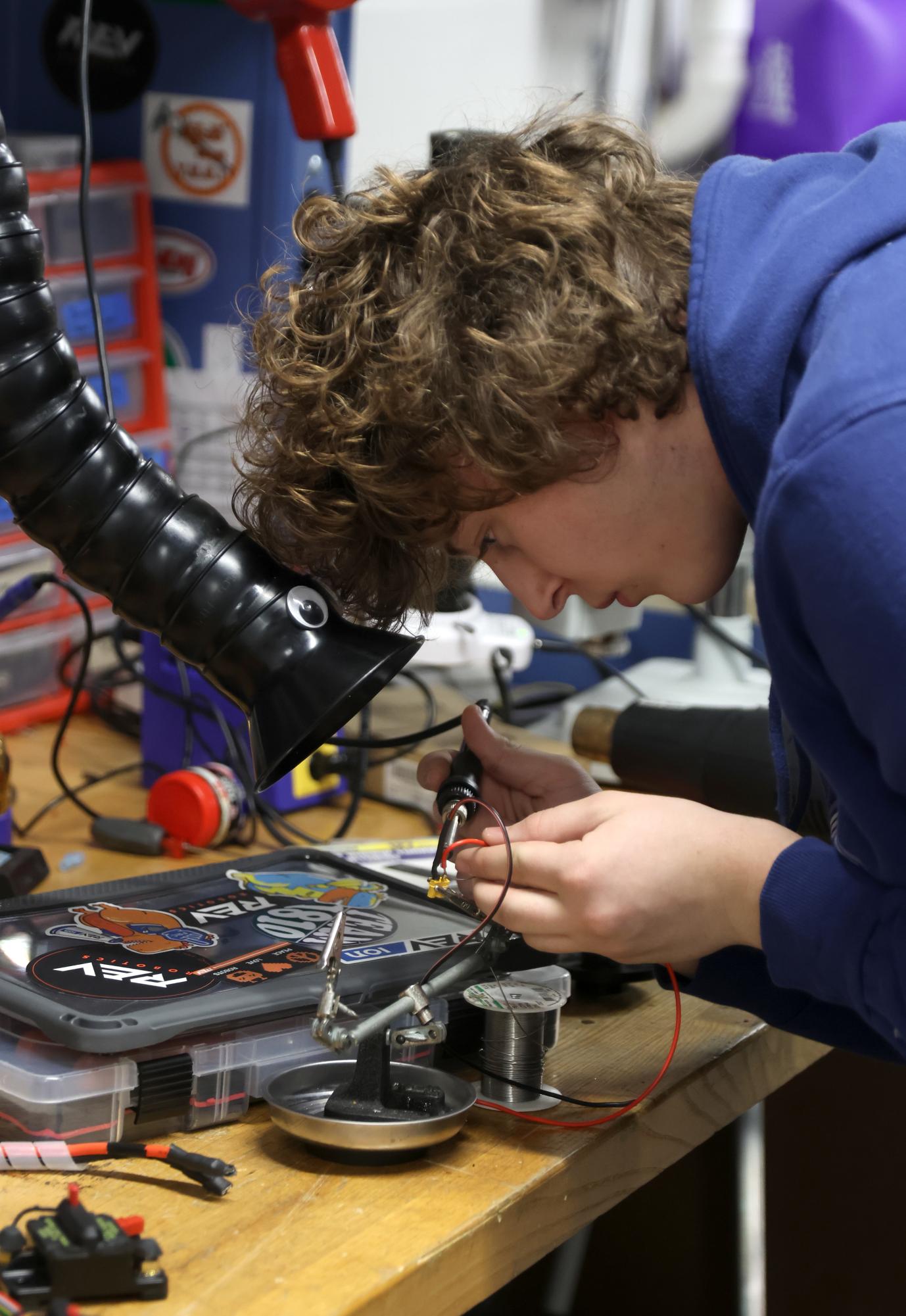

CTEC’s third and final strand, emerging technologies, has classes for students interested in anything from welding to robotics.

Senior Georgia Hansen is in her second year of CTEC classes and is currently taking Digital Electronics and Robotics Capstone. She explains the technology open to emerging technologies students during class.

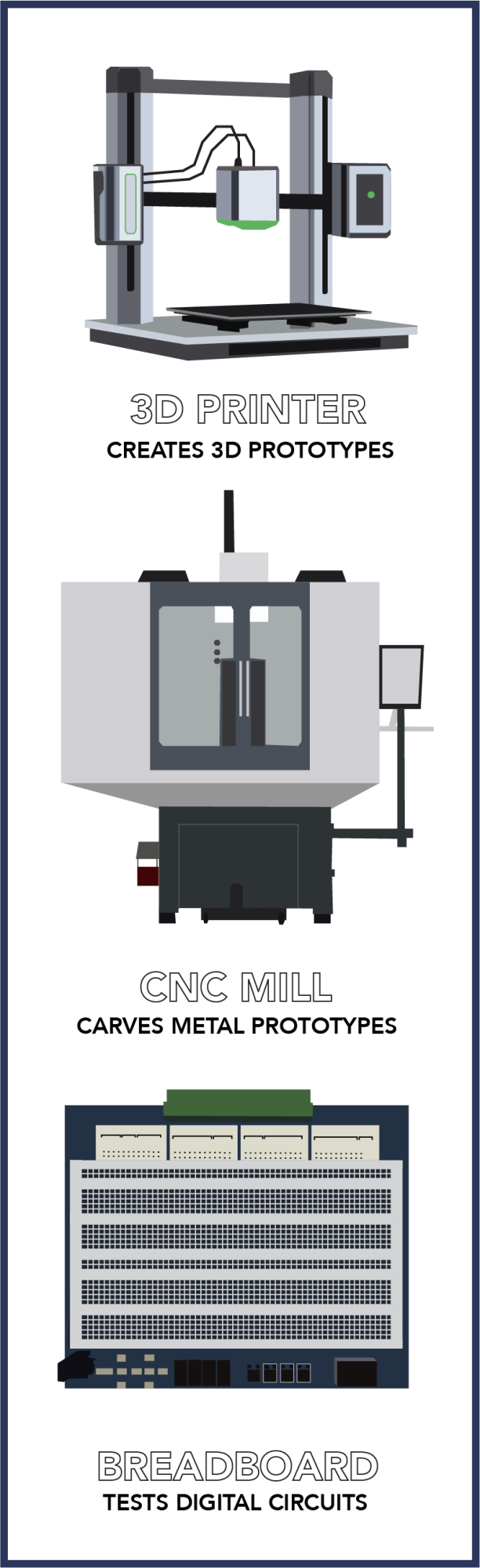

“On the design side, we have great computers for 3D modeling, and that goes for both 3D printing and for [Computerized Numerical Control] models as well,” Hansen said. “On the actual build side, CTEC has so much technology that enables you to rapidly prototype and go from having an idea to holding that in your hands and seeing how it works in a very short amount of time. There are plasma cutters, there are CNC mills, we have tons of 3D printers. We have a whole bunch of woodworking stuff, band saws, circular saws, drills and all of that is open to pretty much every student that is willing to go through the safety explanation for how they should actually operate it.”

Junior Carter Tollman describes how this advanced technology aids in his learning during Digital Electronics.

“In Digital Electronics, we’ve been mostly using breadboards but we’re starting to get into Arduinos,” Tollman said. “A lot of the computers at CTEC are a lot nicer than many of the computers that we had at Mill Valley, so it’s nice for a lot of classes that use more 3d modeling and design software.”

In addition to Digital Electronics, Tollman also takes Engineering Design & Development, AP Computer Science Principles and Robotics. For him, getting to use this technology now is essential preparation for the future.

“A lot of these classes are similar to intro level college stuff,” Tollman said. “It’s the same type of intro level [content] that aren’t necessarily the difficult courses, but it’s about being exposed to a lot of this technology that most students won’t see until like during college or potentially even later into college. It’s nice being able to be exposed to this stuff that you’re going to interact with for potentially a really long time.”

High-level resources are not the only things that make these classes resemble college, the flexibility to utilize different technology in class also creates more freedom than what many high school classes typically have. Hansen explains the many things a student might do during class time with the wide array of digital technology available.

[Class time] can be anything from doing Boolean logic to designing a circuit using a computer simulation software to actually building that circuit using breadboards and physical electronic components,” Hansen said. “We use wires, integrated chips, multimeters and a computer software called Multisim.”

Davis, who takes Computer Integrated Manufacturing and Emerging Technologies in addition to her bioscience strand classes, explains a robotics project she did while using the laser cutter.

(By Avery Cole)

“During COVID, a bunch of teachers had to use these clear acrylic shields as a cough guard or sneeze guard, so now they have just an extreme excess of this really expensive, high-quality material,” Davis said. “So we went around to a bunch of schools and we picked some of that material up. Now we’re using it in the laser cutter to work on different projects, like a laundry chute for the bridge [and] for the robotics team and the robotics class.”

Similarly to Davis’s project, Hansen worked on a year-long project in her Engineering Design & Development class last school year. The project would not have been possible without the high-level technology offered at CTEC.

“My group made a frisbee launcher and one of the things that we needed for that was a wooden frame,” Hansen said. “So what we did was we made a flat digital sketch of the parts that we needed and then we sent that over to the large CNC woodmill that we have. It was able to cut out the parts pretty much perfectly, very quickly and that was really useful because not only did it allow us to actually build a thing very quickly, but it also gave us really precise cuts that helped us improve our accuracy and our power and make the [launcher] really work.”

Hansen explains why being able to create projects like these is an important part of the learning experience at CTEC and why this would not be possible without technology.

“Technology is really crucial for us to be able to understand how our designs would relate to the real world,” Hansen said. “When you just have it on paper, it’s really hard to tell if something would actually work or not. You’re going to have a great idea in your head, but when you put it into reality, you realize, ‘oh, these two parts don’t fit together’ or ‘I designed this wrong – this was supposed to be right handed but ended up left handed’ and that’s not something that you would think about when you’re making the design, but when you really have the prototype right in front of you, thanks to the technology, you can very clearly see what worked on your design, what didn’t and what you need to improve.”

CTEC CAPS Administrator Tim Mispagel believes that no matter the strand, CTEC provides unparalleled opportunities for high schoolers.

“Having access to this equipment is as close to industry as they’re going to get in high school,” Mispagel said. “[The] equipment our students are being trained on could translate into an immediate job opportunity or internship opportunity for students that are in high school. So the overall objective is to try to get our students, whether it’s engineering, cybersecurity, manufacturing, into some type of a learning experience that will translate into a job as quickly as possible.”